Class II (Distorted Hub Doubling):

The next class, Class II, is harder to find empirical evidence to conclusively prove the cause of the Hub Doubling. Most often hypothesized as the misalignment event relating to either the Die or the Hub, which has expanded or contracted too much in relation to the first hubbing during the annealing or tempering processes.

Class II is characterized by having a spread along the outside devices that goes toward the Center (C) or towards the Edge (E). The order of hubbings is typically determined by presuming that the deeper hubbing comes last whilst the lighter hubbing occurred earlier.

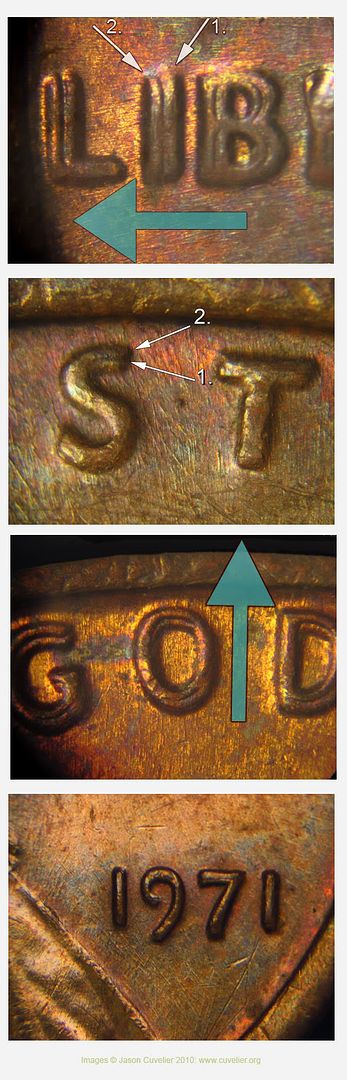

Dies are annealed (cooled slowly) to make them softer so they are more susceptible to taking an impression of the Hub. The Hub in contrast is tempered, quickly cooled, so that it is more durable and does not distort while transferring an image to the Die. If for whatever reason, either the Die or the Hub were not to return to its normal size in between hubbings, doubling could result like the illustration below (1971S DDO-001) where doubling would be more pronounced toward the rims and would either be spread away from or towards the center of the die:

Next is a fictitious illustration showing a 1960 which gives an indication of how the doubling can be spread toward the center or away from the edge (rims):

Let’s clarify the direction of the spread. Here we have 1971P DDO-001 (1-O-II-E) 1DO-001, the design elements inside (closer to the center) were hubbed first and then was followed by the somewhat deeper second hubbing that lies closer to the edge (rim):

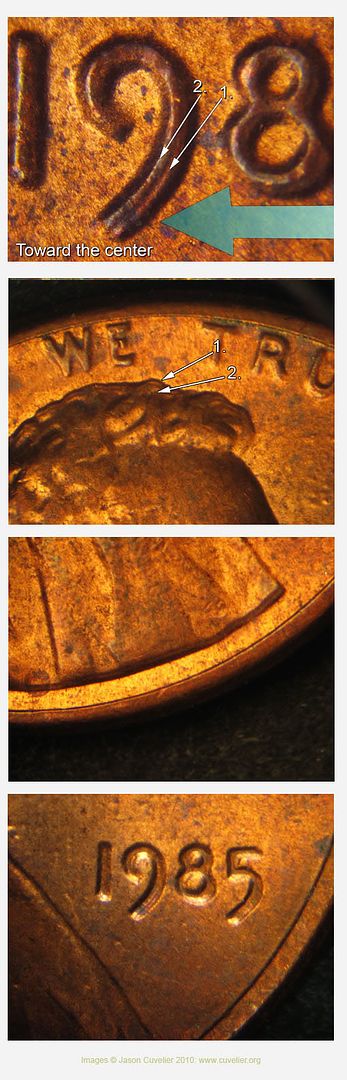

The inverse shown below is a 1985P DDO-001 (1-O-II-C) 1DO-001 which shows the outer impression (closer to the edge) being hubbed first while the inner, deeper impression was hubbed last:

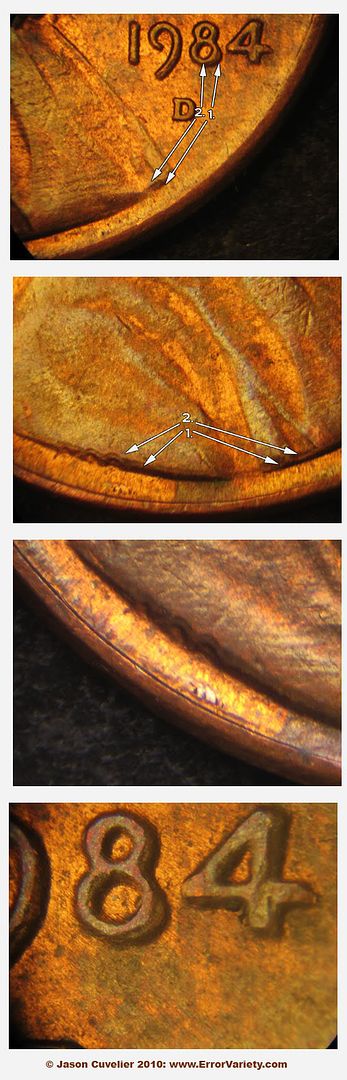

1984D DDO-001 (1-O-II C + VI) also shows, to a degree like 1985P DDO-001 up above, how far into the design Class II doubling can be present in that the the lower bust and VDB are clearly doubled as well. And where are the rest of the doubled devices? As with Class I and V, the doubling is more pronounced on the outer edges. The inner design elements would have both been barely doubled and the second hubbing likely would have obliterated it towards the center.

Below is another illustration showing two hubbings spread toward the center (C) on a fictitious 1985D Lincoln cent (similar to the ‘85P and '84D above): the initial impression, which in this case is outer (red) and the inside, final impression (green):

Welcome guest, is this your first visit? Click the "Create Account" button now to join.

Results 1 to 10 of 13

Threaded View

-

07-13-2010 #1

Class II (Distorted Hub Doubling):

Last edited by jcuve; 08-22-2010 at 09:22 AM.

Jason Cuvelier

MadDieClashes.com - ErrorVariety.com

TrailDies.com - Error-ref.com - Port.Cuvelier.org

CONECA

(images © Jason Cuvelier 2008-18)___________________

-

Post Thanks / Like - 1 Thanks, 1 Likes

Reply With Quote

Reply With Quote

Bookmarks